जल शीतलन एकल दीवार घुमावदार पाइप एक्सट्रूज़न लाइन

यह उन्नत विनिर्माण समाधान उच्च-गुणवत्ता वाले तरंग वाले पाइपों का उत्पादन करता है, जो उत्कृष्ट प्रदर्शन और विश्वसनीयता के साथ हैं।यह कुशलता से एक दीवार वाले नालीदार पाइपों का निर्माण करता है जिनका उपयोग जल निकासी प्रणालियों में किया जाता है, विद्युत conduits, और विशेष पाइपिंग अनुप्रयोगों.

मुख्य प्रौद्योगिकी और प्रदर्शन

सीमेंस के मुख्य मोटर द्वारा संचालित, जो उत्कृष्ट प्रदर्शन और स्थायित्व के लिए जाना जाता है, यह एक्सट्रूज़न लाइन स्थिर संचालन, उच्च दक्षता और कम ऊर्जा खपत सुनिश्चित करती है।मजबूत मोटर डिजाइन न्यूनतम डाउनटाइम के साथ निरंतर चलने का समर्थन करता है, इसे उच्च मात्रा में उत्पादन वातावरण के लिए आदर्श बनाता है।

सामग्री संगतता

उत्पादन लाइन एचडीपीई, पीई, पीवीसी और पीपी सहित उच्च गुणवत्ता वाले कच्चे माल को संसाधित करती है। ये सामग्री उत्कृष्ट यांत्रिक गुण, रासायनिक प्रतिरोध और लचीलापन प्रदान करती हैं, जिससे टिकाऊ सुनिश्चित होता है।,विभिन्न उद्योग आवश्यकताओं के लिए दीर्घकालिक पाइप।

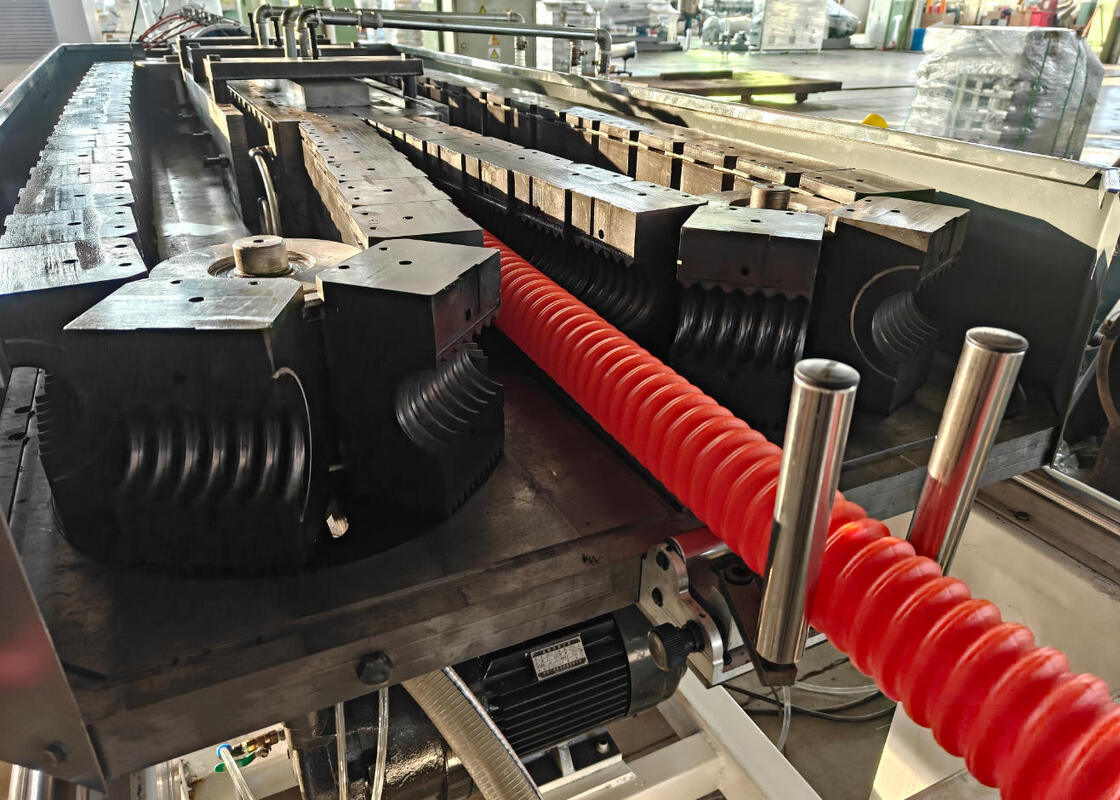

उन्नत शीतलन प्रणाली

जल शीतलन विधि एक्सट्रूडेड पाइपों को तेजी से और समान रूप से ठंडा करती है, जिससे आयामी स्थिरता और सतह की गुणवत्ता बढ़ जाती है।यह पर्यावरण के अनुकूल समाधान पाइप की अखंडता बनाए रखते हुए निरंतर उत्पादन गति बनाए रखता है.

विद्युत कंडक्ट का उत्पादन

यह प्रणाली उच्च गुणवत्ता वाले विद्युत conduits का उत्पादन करती है जो सख्त उद्योग मानकों को पूरा करते हैं, आवासीय, वाणिज्यिक,और औद्योगिक प्रतिष्ठानों.

स्वचालन एवं नियंत्रण

पीएलसी नियंत्रण प्रणाली से लैस, यह लाइन उन्नत स्वचालन के साथ उपयोगकर्ता के अनुकूल संचालन प्रदान करती है।प्रक्रिया मापदंडों की वास्तविक समय की निगरानी और समायोजन पाइप की निरंतर गुणवत्ता और कम सामग्री अपशिष्ट सुनिश्चित करता है.

प्रमुख विशेषताएं

उत्पाद का नाम

सिंगल वॉल वेरिफाइड पाइप एक्सट्रूज़न लाइन

उपयुक्त सामग्री

एचडीपीई, पीई, पीवीसी, पीपी

नियंत्रण प्रणाली

पीएलसी नियंत्रण

वितरण बंदरगाह

क़िंगदाओ, शेडोंग प्रांत

परत विकल्प

एकल दीवार और डबल दीवार

अतिरिक्त क्षमताएं:

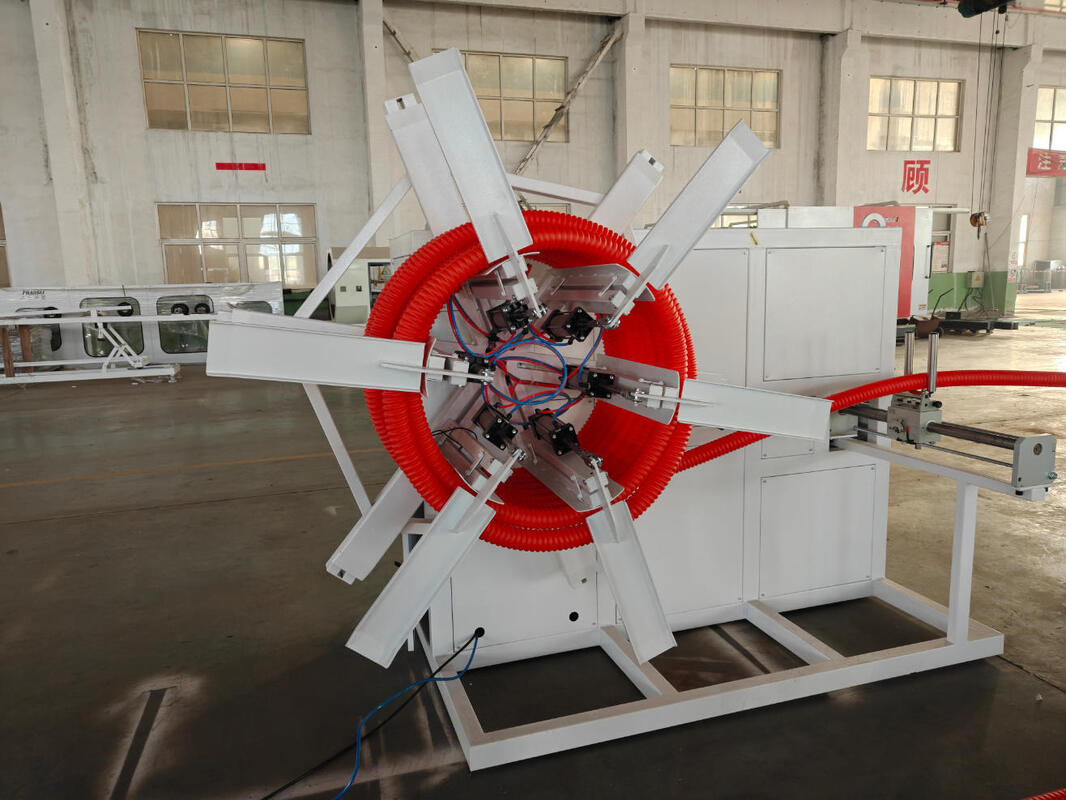

- कुशल उत्पादन के लिए उच्च-गति वाले तरंगित पाइप एक्सट्रूज़न

- गुणवत्ता और स्थायित्व सुनिश्चित करने वाली उन्नत मशीनरी

- बहुमुखी अनुप्रयोगों के लिए पूर्ण उत्पादन लाइन

तकनीकी विनिर्देश

| पैरामीटर |

विनिर्देश |

| शीतलन विधि |

जल शीतलन |

| मुख्य मोटर |

सीमेंस |

| शीतलन मोड |

जल शीतलन |

| पोर्ट |

क़िंगदाओ, शेडोंग प्रांत |

| नियंत्रण प्रणाली |

पीएलसी |

| उपयुक्त सामग्री |

एचडीपीई / पीई / पीवीसी / पीपी |

| परिवहन पैकेज |

विदेशी मानक पैकेज |

| अनुशंसित कच्चा माल |

पीई, पीपी, पीवीसी |

| परत |

एकल दीवार, दोहरी दीवार |

आवेदन और आदेश की जानकारी

HUASU सिंगल वॉल वेरिगेटेड पाइप एक्सट्रूज़न लाइन (मॉडल SBG) CE और ISO मानकों द्वारा प्रमाणित है, जो विश्वसनीय प्रदर्शन और गुणवत्ता आश्वासन सुनिश्चित करता है।यह बहुमुखी उत्पादन समाधान टिकाऊ, लचीले तरंगित पाइप के लिएः

- विद्युत नलिकाओं की सुरक्षा प्रणाली

- जल निकासी और सीवरेज प्रणाली

- केबल सुरक्षा और प्रबंधन

- एचवीएसी और वेंटिलेशन अनुप्रयोग

- सिविल इंजीनियरिंग और अवसंरचना परियोजनाएं

- दूरसंचार उपकरण

आदेश विवरणः

वार्षिक आपूर्ति क्षमताः 100 सेट

न्यूनतम आदेश मात्राः 1 सेट

मूल्य सीमाः 10,000 अमरीकी डालर - 1,000,000

वितरण समयः 60-90 दिन

भुगतान की शर्तें: टी/टी, एल/सी

पैकेजिंगः कंटेनर मानक और विदेशी मानक पैकेज

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews